Note: NZR products require specific design criterion and analysis of DoT rules for application in each Country. Please contact NZR for best design solutions for your area.

Goal is to assist industry transition toward a genuine integration of tractor and trailer as follows:

- To reduce Semi-trailer “GAP” improve fuel economy and freight capacity

- ACCORD 63, 67, 73′ Semi-trailers (d-train 5th wheel compound hitch)*

- To reduce off-tracking

- 53, 57, 60, 63 & 67′ semi-trailers (SST Steering Bogies)*

- To reduce forward length

- Accord non-articulated Semi-trailers

- Semi-trailers (SST Steering Bogies)*

- To reduce articulation points in “Double” trailers

- Twin Uni-draw bar converter dollies (A/C-trains)*

- To improve ratio from 1:1 to 1:3 with demount-able, ancillary equipment (Bodies) on vocational trucks

- Tanks, Dumps, Roll-off, Garbage, Vans, with d-train hitch system*

- To reduce tire scuffing (tandem& Tri-axle) with SST Steering Bogies*

- Vocational Semi Dumps trailers with SSA Slip-Steering Axle*

- To reduce full tractor/trailer jackknifing & Roll Over

- Accord Semi-trailer (d-train hitch)*

- To reduce road pavement damage by changing footprint

- *All products Patented other Patents Pending

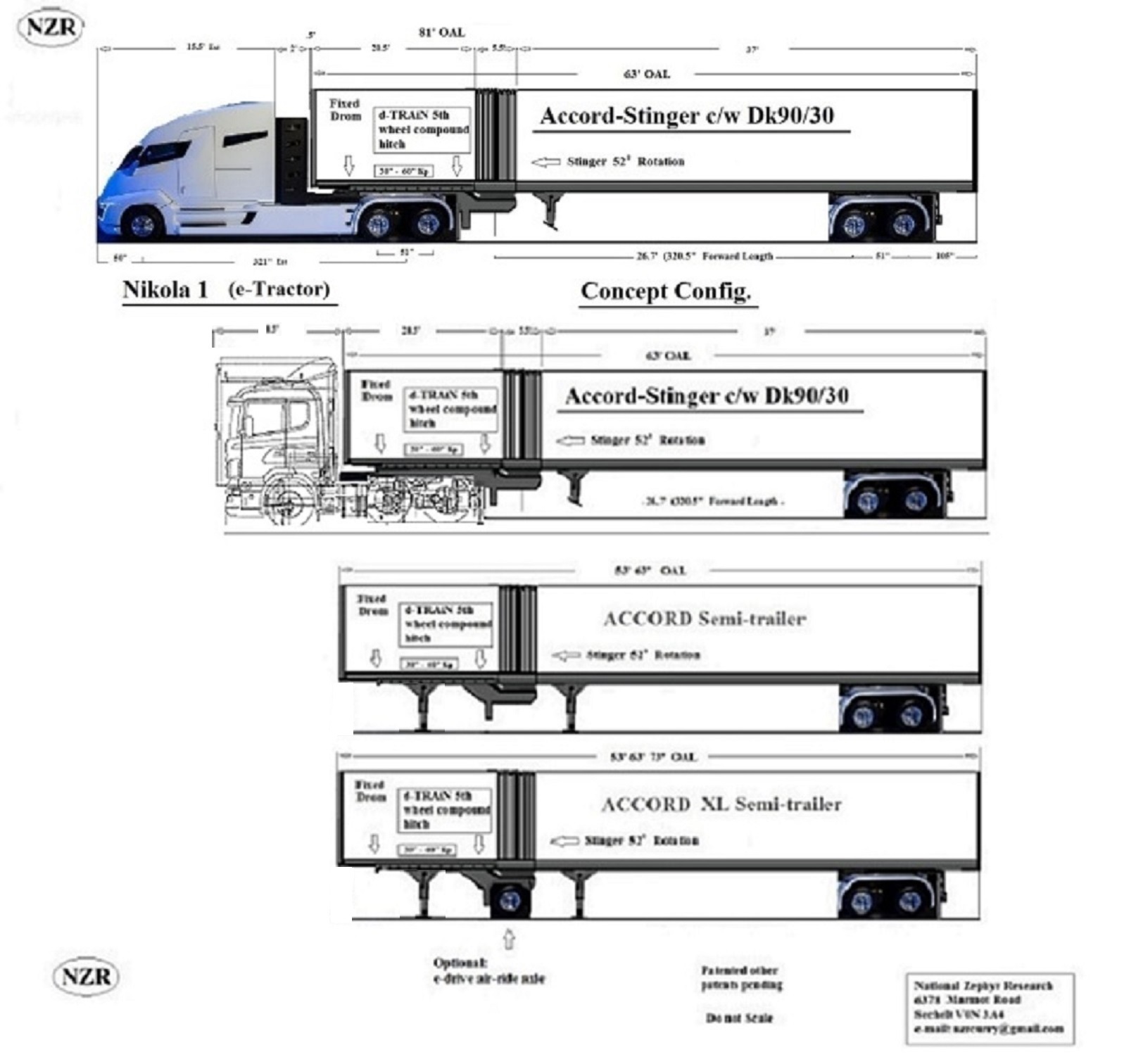

Truck/tractor and Semi-trailer design prototyping has become something of an art form with NZR; not the least of which has been the recent availability of e-axles. Indeed the new e-tractors are exciting yet still exhibit the same characteristics, jackknife, GAP and poor maneuverability. They overlook an opportunity for inter-connectivity, lot’s of low hanging fruit in this area. With the d-Train 5th Wheel Compound Hitch on offer, substantial reliability and productivity gains are possible.

The d-Train ACCORD Semi-trailer is an example of this and could open the door to opportunities previously not thought possible. A change toward connectivity is a real opportunity for industry.

Time to see through the haze, to be inspired

Integration:

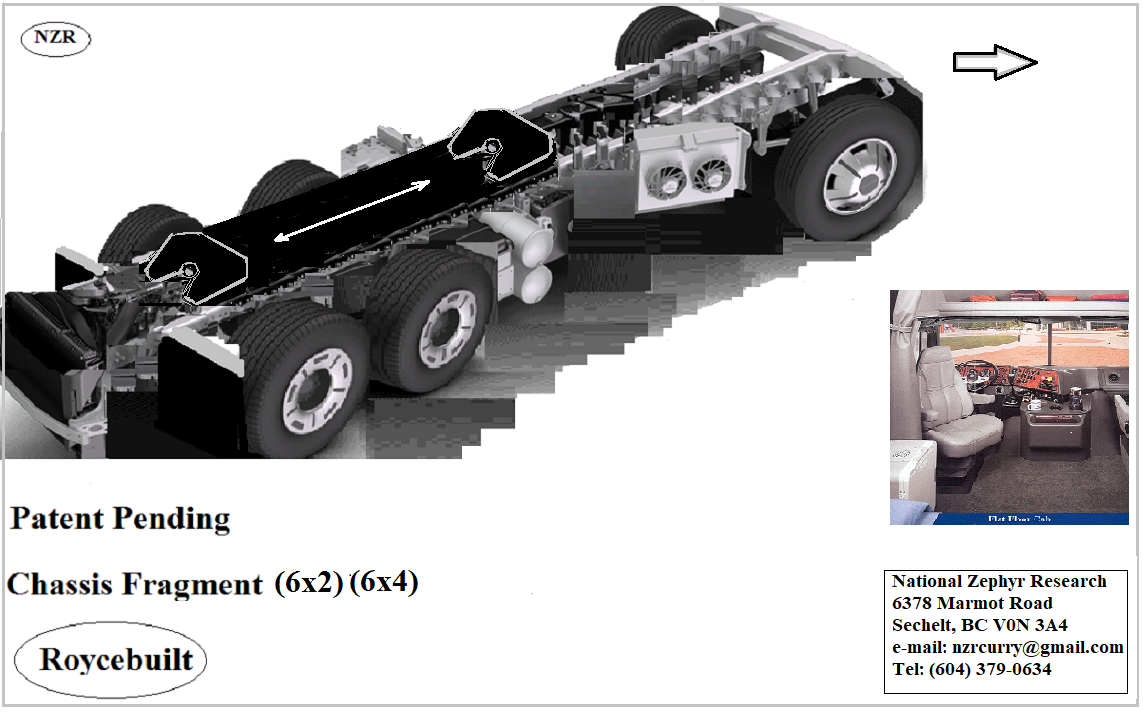

The next generation 2020 power unit design must make provision for integrating, both truck and trailer. Present day truck/tractor Semi-trailer design is mostly, straight out of a Norman Rockwell painting. Tesla, Nikola et al, now e-battery power are a great innovation. However calling these vehicles the next generation is a bit of a stretch. GHG notwithstanding, what a missed opportunity for the trailer innovation and reliability. The Mega-bucks being spent on e-trucks, the Supertruck l & ll R&D project and others are but examples. What is needed is integration of the truck and trailer connection. And to proffer this integration as a priority. OEM integration using SAE standards to include all class V, Vl, Vll, and Vlll Diesel and e-Truck, models are candidates.

New Truck Chassis c/w d-Train compound hitch

Fueling the future

EPA has done a good job in energizing concerns for reduced fuel consumption and mitigation of GHG the overall move away from fossil fuels encouraging. Nevertheless, the hubbub around Supertruck ll R&D continues to overlook integration. Here are two good examples using the patented ACCORD-Stinger Semi-trailer and e-Axle for no-jackknife mechanical control. Closing the “GAP” improves fuel economy, reduces e-demand, improves operating ratio. The no-full jackknife feature of the ACCORD-Semi is a plus when considering these expensive new technology tractors.

Example: e-ACCORD 3 Axle and Hyudai HDC-6 Hydrogen

Example: ACCORD Semi-Trailers Nikola e-1